Products

White Fused Alumina

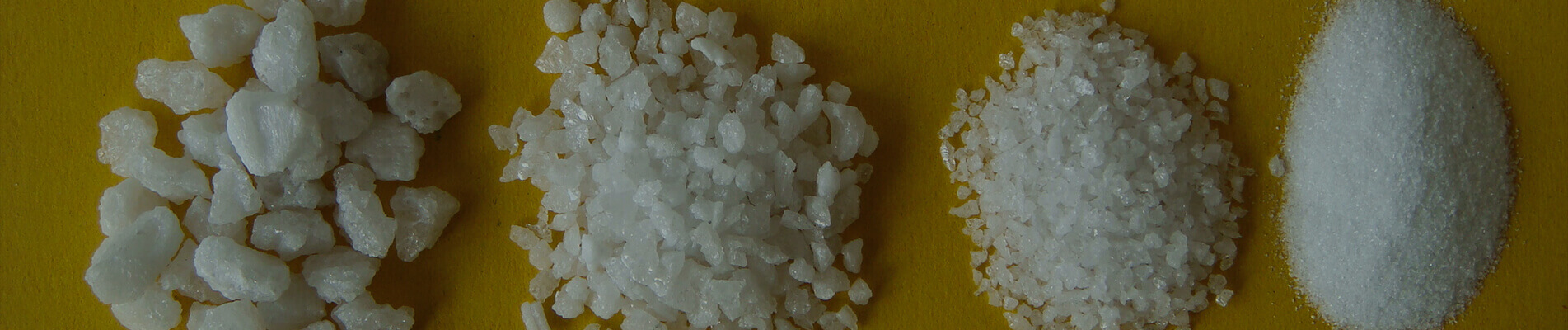

White fused alumina is made from high quality alumina powder by smelting at 2050 ℃, characterized by high purity, good self-sharpening, less thermal diffusivity in grinding, strong acid-alkali resistance, excellent high-temperature stability, low porosity, etc. White fused alumina products including section sand, grain-size sand; fine powder and micro powder are widely used in refractories, abrasives and other industries.

Description

Section sand and fine powder are the main raw materials for the mid-and-top-grade unshaped and shaped refractories, that are widely used in unshaped refractory products like ladle castable, iron runner, gun-mix refractory, etc. In the production of shaped products, they are mainly used for making corundum products like corundum brick, corundum mullite sagger, three major steel-making and continuous-casting pieces and ultra-temperature industrial furnace liner.

Grain-size sand is mainly used as abrasives, a perfect choose for various sand blasting and grinding operations in the abrasive industry, such as the sand blasting in TV screen processing and tooth mold cleaning. Besides, it also can be used as the foundry sand in precision casting and the raw materials of ceramic and resin bonded abrasives as well as coated abrasives.

Specifications

The chemical composition table of White fused alumina:

|

Purpose |

Specification |

Chemical composition(%) |

Magnetic material content(%) |

||||

|

Al2O3 |

Na2O |

SiO2 |

CaO |

|

|||

|

For refractory |

Size sand |

0-1mm

1-3mm

3-5mm

5-8mm |

99.2Min |

0.3 Max |

0.1Max |

0.5 Max |

0.001 Max |

|

Fine powder |

180#-0

200#-0

320#-0 |

99.0Min |

0.4 Max |

0.1 Max |

0.6Max |

0.003 Max |

|

|

For abrasive |

F |

12#—80# |

99.0Min |

0.3Max |

0.1 Max |

0.4 Max |

0.003 Max |

|

90#—150# |

98.5Min |

0.4Max |

0.1 Max |

0.003 Max |

|||

|

180#—240# |

98.2Min |

0.5Max |

0.1 Max |

0.4 Max |

0.002 Max |

||

Physical composition table of White fused alumina:

|

Mohs Hadness |

≥9 |

|

Melting Temperature(℃) |

2050 |

|

Refractory Temperature(℃) |

1900 |

|

True Density (g/cm3) |

≥3. 90 |

GET IN TOUCH

If you have any needs, please leave a message to us, we will reply you as soon as possible.