Products

Magnesia Alumina Spinel

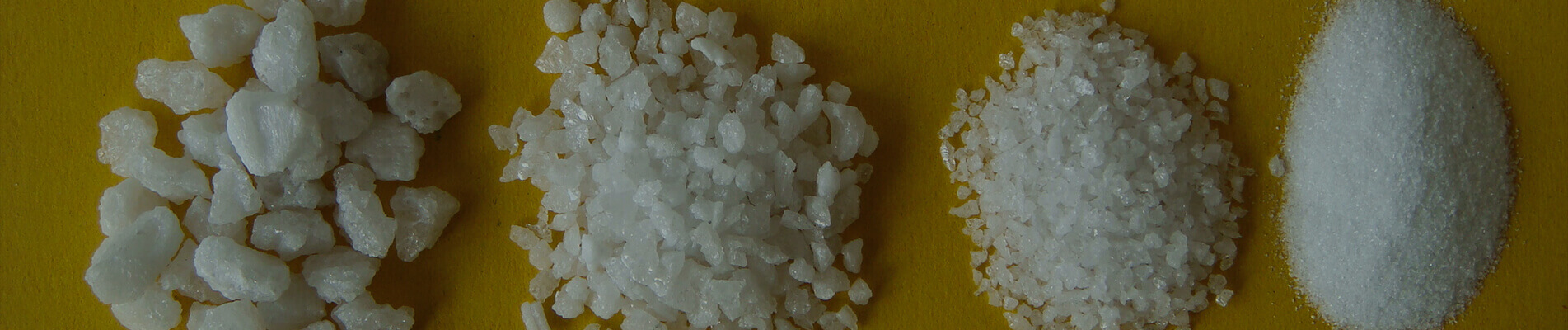

Fused magnesia-alumina spinel is made mostly of alumina powder and high-purity light calcined magnesia powder by smelting at over 2000 ℃ in the electric-arc furnace, characterized by high bulk density, good seismic stability, strong corrosion resistance and slag resistance, etc.

Description

Magnesia alumina spinel plays an indispensable role in refractory industry, widely used in iron and steel melting, cement rotary kiln and glass furnace, as the ideal material for manufacturing continuous-casting sliding plate, nozzle brick, ladle brick and open hearth furnace brick, as well as the basic material for the lining brick of transition zone in large and medium cement kilns, refractory castable and medium-high-temperature kiln furniture brick.

Specifications

Fused Magnesium Aluminum Spinel’s detailed indexes table:

|

properties/designation |

AM-90 |

AM-80 |

AM-70 |

|

|

|

AL2O3 |

88-92 |

82-87 |

71-76 |

|

MgO |

8-12 |

12-17 |

22-27 |

|

|

CaO |

≤0.4 |

0.4 |

0.6 |

|

|

Fe2O3 |

≤0.35 |

0.35 |

0.35 |

|

|

SiO2 |

≤0.25 |

0.4 |

0.4 |

|

|

real density (g/m³) |

≥3.3 |

|||

|

grain size of section sand (mm) |

0-1/1-3/3-5/5-8 |

|||

|

powder (mesh) |

-180 -220 -240 -320 |

|||

|

usage

|

As the important raw material for manufacturing refractory products and fine ceramics, widely used in refractory material products as for making the steel furnace roofs, converters and ladles, the ecotone bricks of large rotary cement kiln, and the glass furnace regenerators, etc. |

|||

GET IN TOUCH

If you have any needs, please leave a message to us, we will reply you as soon as possible.